Request A Quote

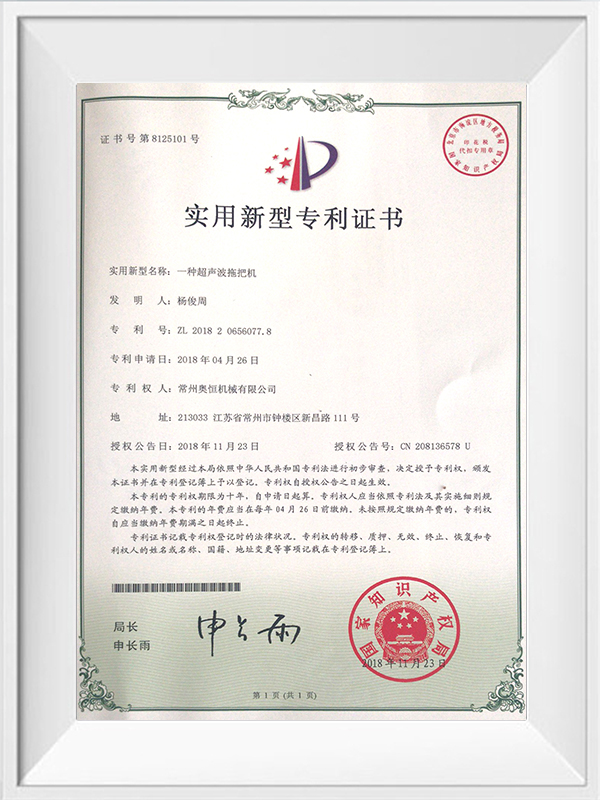

Introduction to Ultrasonic Towel Cutting Machines An ultrasonic towel cutting machine is a specialized piece of equipment used in the textile industry to cut towel fabrics with precision, speed, and m...

View MoreMeeting High Output Demands in Large-Scale Towel Manufacturing Large-scale towel production is driven by continuous orders, fixed delivery schedules, and strict dimensional requirements. Manual or sem...

View MoreBag sealing is a critical process in packaging, ensuring products are protected from contamination, leakage, and spoilage. Two common methods for sealing plastic and laminated bags are ultrasonic seal...

View MoreThe Impact of Ultrasonic Welding on Product Quality and Durability

Ultrasonic welding has revolutionized the manufacturing landscape by significantly enhancing product quality and durability. This innovative technology generates high-frequency vibrations that create frictional heat, allowing materials—particularly plastics and fabrics—to bond seamlessly. The result is a strong molecular joint that rivals the strength of the raw materials themselves.

One of the key benefits of ultrasonic welding is its efficiency. With welding cycles lasting between 0.01 to 9.99 seconds, manufacturers can achieve rapid production rates while maintaining high-quality standards. This not only minimizes defects but also maximizes productivity. Additionally, the robust bonds formed through ultrasonic welding ensure that products can withstand substantial stress, making them ideal for critical applications in automotive, electronics, and medical devices.

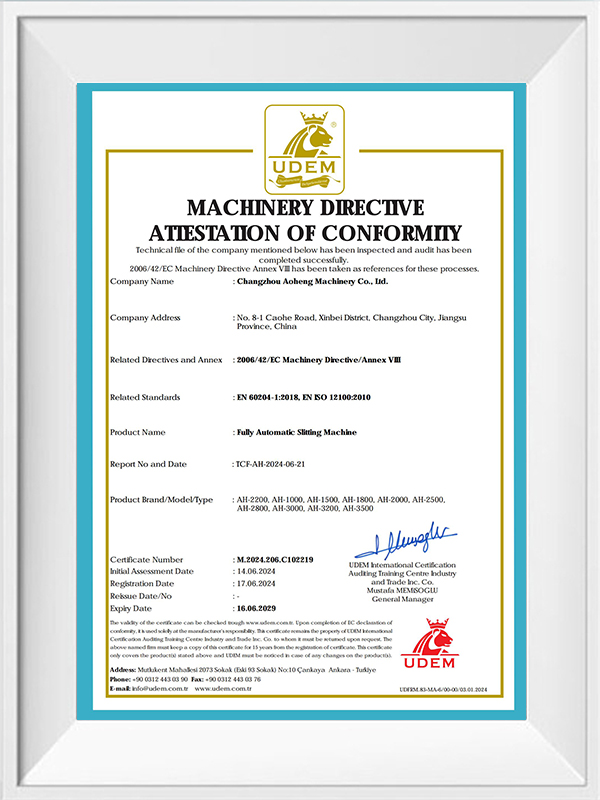

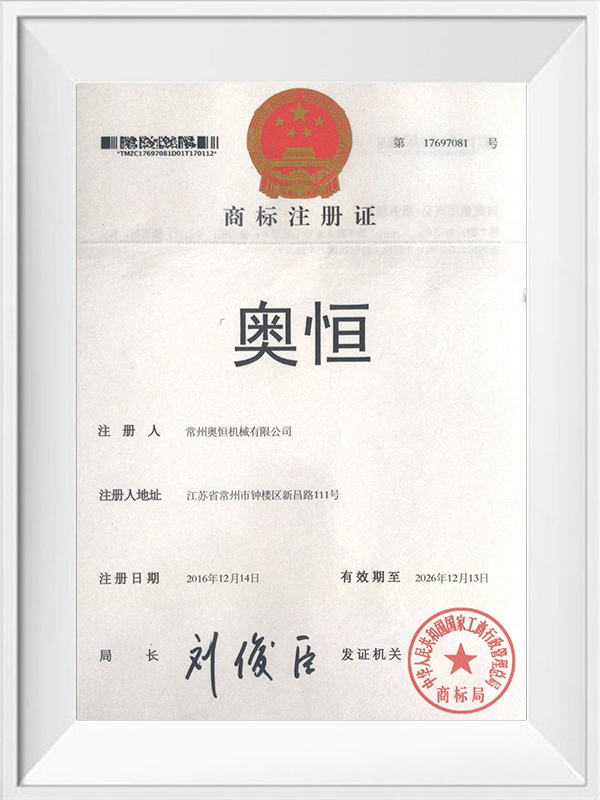

At AOHENG, we utilize ultrasonic welding to produce high-quality components that meet the stringent demands of various industries. Our state-of-the-art machines ensure consistent performance, resulting in durable products that exceed customer expectations.

AOHENG's commitment to advanced welding technology underscores our dedication to providing exceptional products that stand the test of time.

The Science of Sound: How Ultrasonic Frequencies Achieve Effective Welding

Ultrasonic welding is a cutting-edge technology that uses high-frequency sound waves, typically between 15 kHz and 20 kHz, to create strong bonds between materials without adhesives. This innovative process converts electrical energy into mechanical vibrations that generate frictional heat, melting the materials at their interfaces and allowing them to fuse seamlessly.

The welding process begins with a generator producing high-frequency electrical signals, which are then transformed into mechanical vibrations by a transducer. When these vibrations are applied, they create heat that quickly raises the temperature at the contact points, allowing the materials to bond as they cool under pressure. With welding cycles lasting only 0.01 to 9.99 seconds, this method ensures rapid production while maintaining exceptional quality.

Ultrasonic welding offers several advantages, including strong joints that can withstand significant stress and the elimination of auxiliary materials, making it environmentally friendly and cost-effective. At AOHENG, we utilize advanced ultrasonic welding technology to manufacture high-quality products tailored to meet the stringent demands of various industries. Our precise and efficient welding solutions ensure that our components are reliable and durable, providing our customers with outstanding value.