Request A Quote

Introduction to Ultrasonic Towel Cutting Machines An ultrasonic towel cutting machine is a specialized piece of equipment used in the textile industry to cut towel fabrics with precision, speed, and m...

View MoreMeeting High Output Demands in Large-Scale Towel Manufacturing Large-scale towel production is driven by continuous orders, fixed delivery schedules, and strict dimensional requirements. Manual or sem...

View MoreBag sealing is a critical process in packaging, ensuring products are protected from contamination, leakage, and spoilage. Two common methods for sealing plastic and laminated bags are ultrasonic seal...

View MoreHow Does Ultrasonic Technology Enhance Sewing Efficiency in Modern Manufacturing?

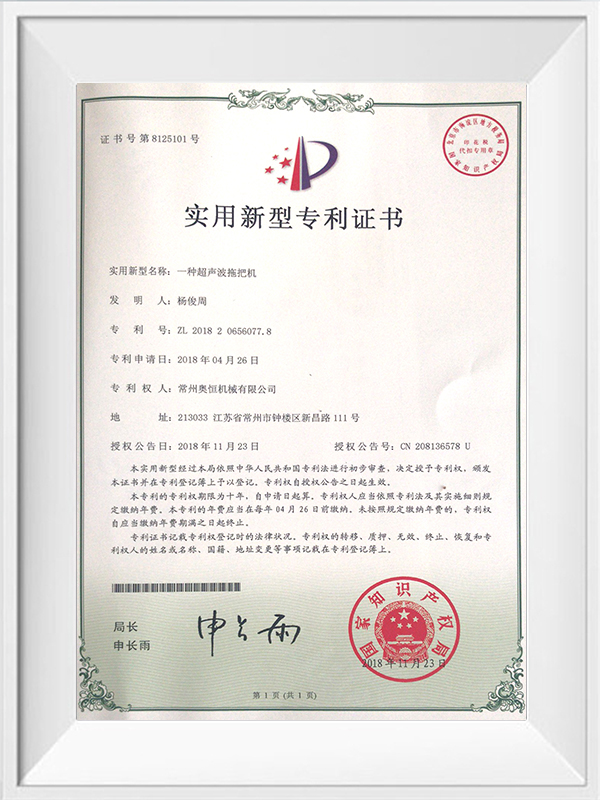

Ultrasonic technology is transforming sewing efficiency in manufacturing by replacing traditional needle-and-thread methods with high-frequency sound waves. These waves generate friction at the molecular level, melting and bonding materials instantly. This process eliminates the need for thread, speeds up production, and reduces labor costs. Additionally, ultrasonic sewing handles cutting, sealing, and embossing in a single step, ensuring precise, clean edges with minimal waste.

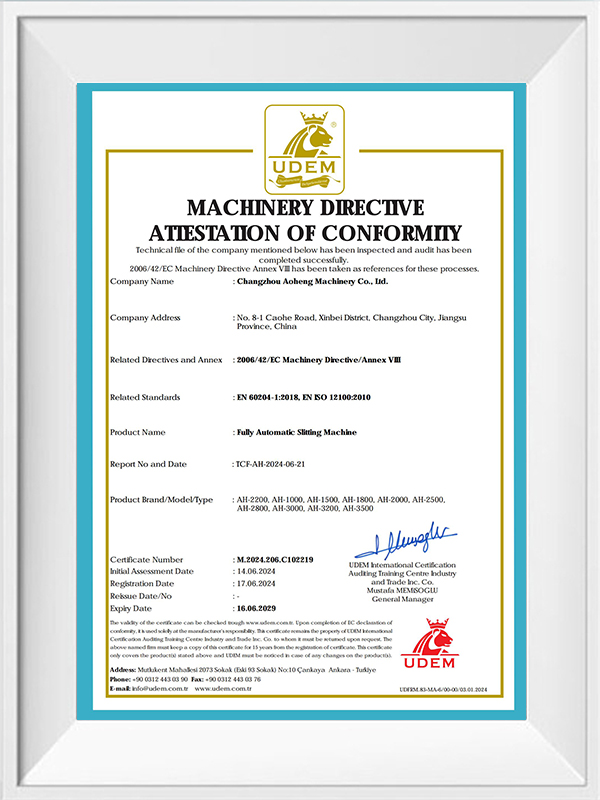

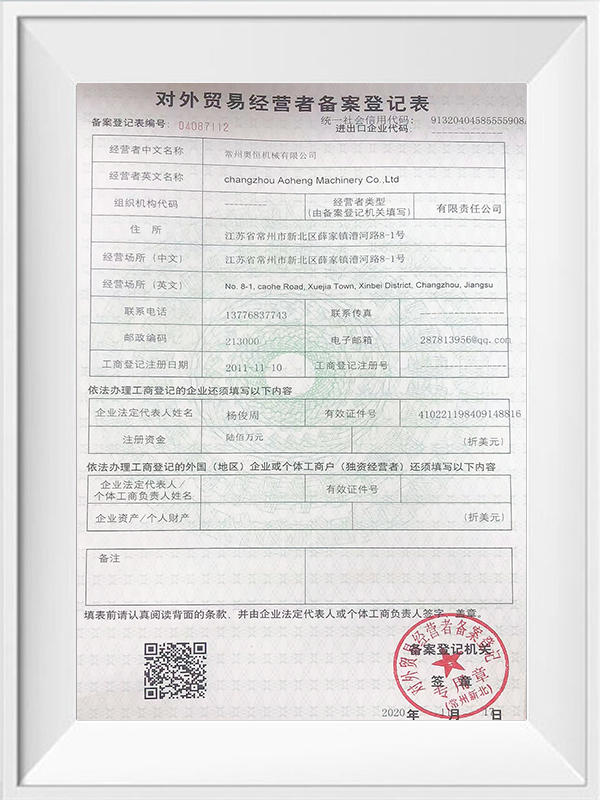

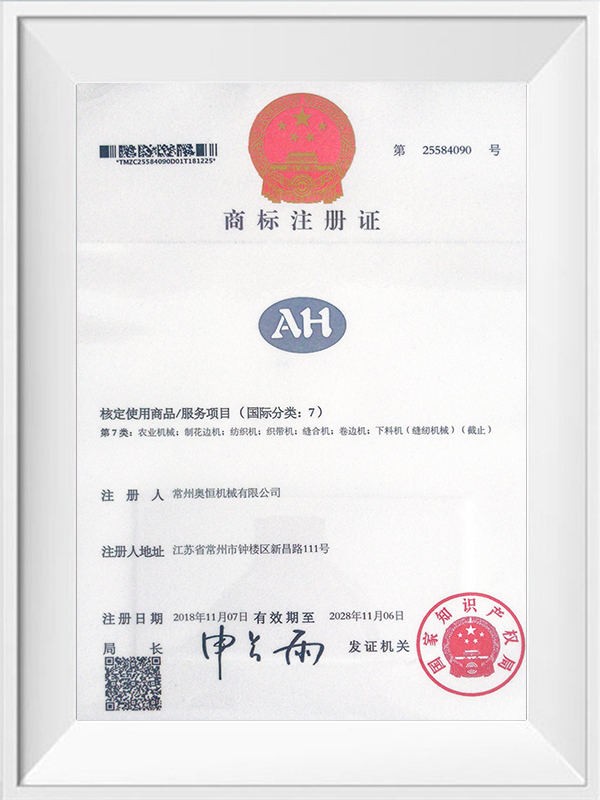

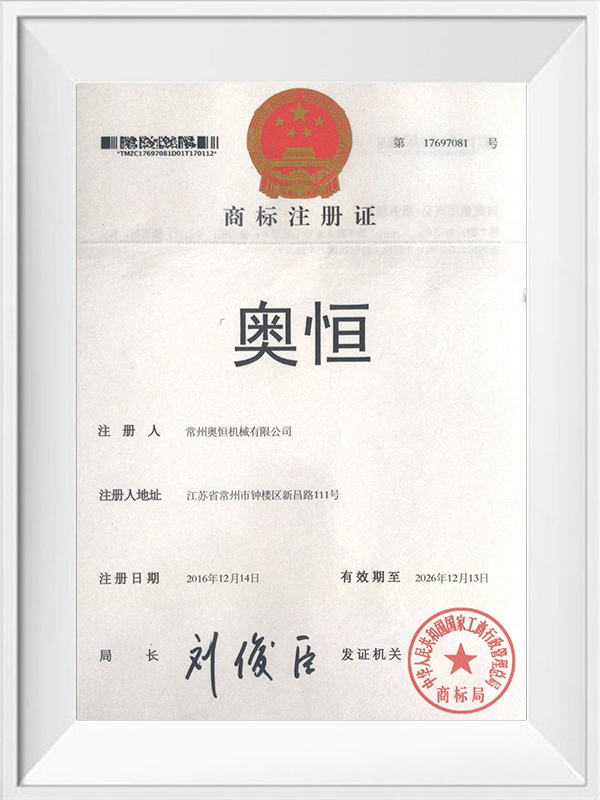

AOHENG’s ultrasonic lace machines offer versatility—performing sewing, cutting, and embossing all in one. Their machines feature low-noise operation, ergonomic design for easy handling, and durable welding heads made from alloy steel for extended use. This ensures manufacturers achieve higher efficiency and product quality while reducing environmental impact.

Ultrasonic technology is a game-changer for modern manufacturing, boosting production speed, cutting costs, and offering sustainable, high-quality results. With AOHENG’s advanced machines, manufacturers can enhance efficiency across a wide range of textile and non-woven applications.

Ergonomics and Safety Considerations When Operating Ultrasonic Lace Machines

In modern manufacturing, prioritizing ergonomics and safety is essential for enhancing operator well-being and productivity. Ultrasonic lace machines, crucial in textile and non-woven processing, should be designed to minimize physical strain and prevent workplace injuries.

An ergonomically designed ultrasonic lace machine reduces operator fatigue and improves efficiency. Key features include adjustable height, user-friendly controls, and intuitive interfaces. AOHENG’s machines are specifically crafted for easy handling, allowing operators to work comfortably without excessive bending or reaching.

Safety is vital when operating ultrasonic lace machines due to the high-frequency oscillation involved. Implementing protective guards, providing proper training, and establishing clear safety protocols can prevent accidents. AOHENG’s machines utilize low-noise 20/8KHZ technology, reducing noise pollution and enhancing workplace safety. Additionally, built-in safety mechanisms help protect operators from potential hazards.

By focusing on ergonomics and safety, manufacturers can create a more efficient and secure working environment. AOHENG’s ultrasonic lace machines are designed to prioritize operator comfort and safety, leading to improved productivity and worker satisfaction.