Request A Quote

Introduction to Ultrasonic Towel Cutting Machines An ultrasonic towel cutting machine is a specialized piece of equipment used in the textile industry to cut towel fabrics with precision, speed, and m...

View MoreMeeting High Output Demands in Large-Scale Towel Manufacturing Large-scale towel production is driven by continuous orders, fixed delivery schedules, and strict dimensional requirements. Manual or sem...

View MoreBag sealing is a critical process in packaging, ensuring products are protected from contamination, leakage, and spoilage. Two common methods for sealing plastic and laminated bags are ultrasonic seal...

View MoreHow to Choose the Right Ultrasonic Slitting Machine for Your Business

Picking the perfect ultrasonic slitting machine can make all the difference in boosting your production and cutting down inefficiencies. Here’s how to make the right choice:

Know Your Material: Whether you're cutting fabrics, ribbons, or synthetic fibers, choose a machine that handles your material perfectly. Ultrasonic slitting gives you smooth, sealed edges with no fraying or loose threads—ideal for high-quality finishes.

Speed Matters: Need to ramp up production? Look for a machine with cutting speeds between 5 and 100 meters per minute, depending on what you’re working with. Faster machines mean faster turnaround times!

Automation for the Win: Tired of manual work? Go for a machine with automated controls, like a PLC touch screen, to save time and labor while ensuring precision with every cut.

Power and Performance: Match your machine’s power and frequency (typically 15-20 kHz) to the thickness and toughness of your materials. The right setup ensures smooth operation and flexibility for different jobs.

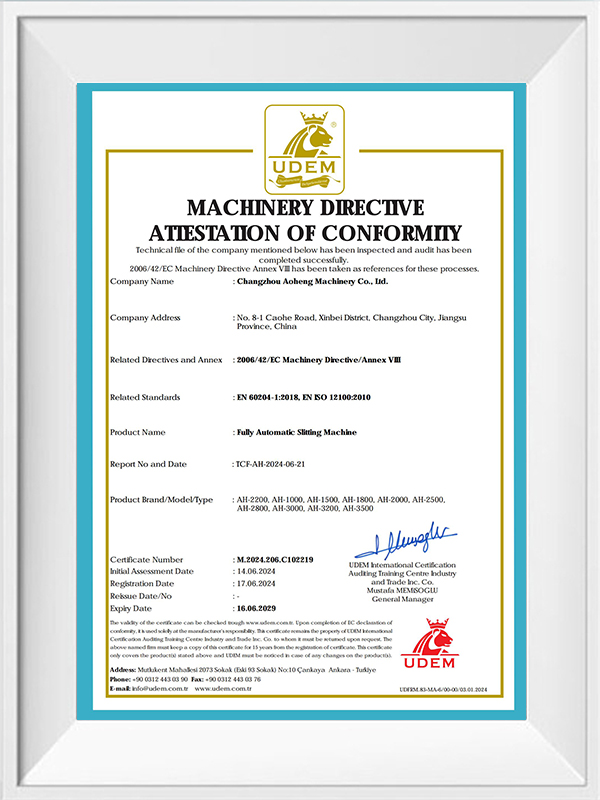

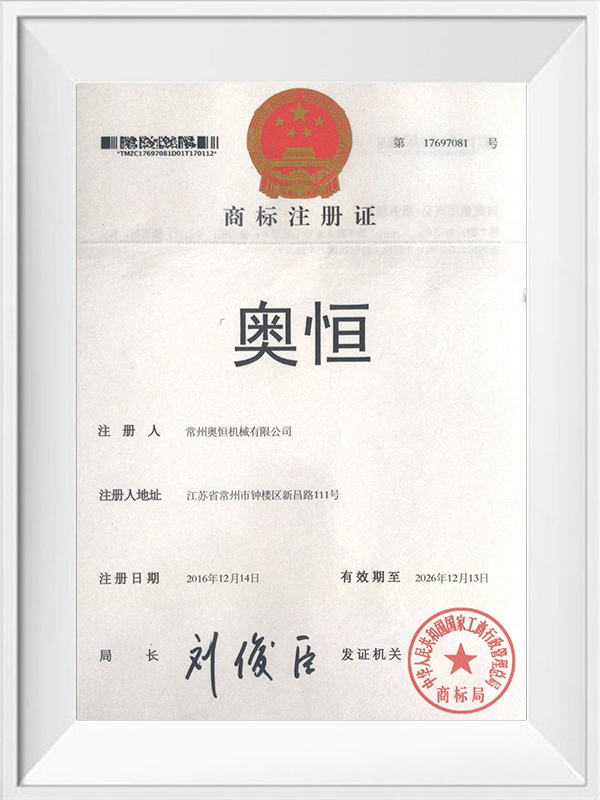

Trust Your Supplier: Choose a brand that backs you up. AOHENG offers top-tier ultrasonic machines with reliable components, like German-imported cylinders and U.S.-made ultrasonic systems. You’ll get both performance and long-lasting durability, plus the support you need to keep things running smoothly.

Make the smart choice—find a machine that fits your needs, and watch your production take off!

Safety Considerations When Operating Ultrasonic Slitting Machines

Operating ultrasonic slitting machines can greatly enhance your production efficiency, but safety should always come first! Here are a few key things to keep in mind to ensure smooth and safe operations:

Proper Training: Before anyone touches the machine, they should be fully trained. Ultrasonic slitting machines use high-frequency vibrations, so operators need to understand how to handle them properly to avoid accidents.

Wear Protective Gear: Safety gloves, glasses, and ear protection are essential. Ultrasonic waves can be loud and high-intensity, so ear protection helps minimize noise exposure, and gloves prevent any unwanted contact with the sharp slitting blades.

Machine Maintenance: Regular checks ensure the machine runs safely and efficiently. Keeping the ultrasonic system, blades, and other components in top shape reduces the risk of malfunction and ensures a longer machine life.

Proper Ventilation: Ultrasonic cutting generates heat, so make sure your workspace is well-ventilated. Proper ventilation will also help avoid any accumulation of dust or fumes from certain materials.

Emergency Stop Function: Always make sure your machine has an easily accessible emergency stop button. In case something goes wrong, a quick shutdown can prevent damage or injury.

At AOHENG, we prioritize safety in all our designs. Our ultrasonic slitting machines come equipped with safety features like easy-to-access emergency stops, and we use high-quality components for stable, reliable operation. This means you get both top performance and peace of mind when running your production.

Stay safe, stay efficient, and keep your operations running smoothly!