Request A Quote

Introduction to Ultrasonic Towel Cutting Machines An ultrasonic towel cutting machine is a specialized piece of equipment used in the textile industry to cut towel fabrics with precision, speed, and m...

View MoreMeeting High Output Demands in Large-Scale Towel Manufacturing Large-scale towel production is driven by continuous orders, fixed delivery schedules, and strict dimensional requirements. Manual or sem...

View MoreBag sealing is a critical process in packaging, ensuring products are protected from contamination, leakage, and spoilage. Two common methods for sealing plastic and laminated bags are ultrasonic seal...

View MoreCustomization Options for Disposable Glove Machines: Meeting Industry-Specific Needs

Disposable glove machines are not one-size-fits-all. Each industry has its unique demands, whether it's producing gloves for sterile medical environments, food service, or industrial use. The ability to customize machinery offers manufacturers the flexibility to adapt to these specific needs. Customizable features include:

Knife Mold Design: Industries may require gloves of different shapes or thicknesses. Custom knife molds allow manufacturers to produce gloves tailored to specific applications, ensuring maximum functionality.

Microcomputer Control Systems: Advanced control systems can be programmed to handle industry-specific production schedules. This includes adjusting material feeding speeds and optimizing glove output for various types of plastics or latex.

Waste Separation: Customizable glove machines can be designed to automatically separate finished products from waste material, reducing manual labor and boosting production efficiency.

Meeting Industry Demands with Custom Features

Food Industry: In food processing, disposable gloves must meet hygiene standards while being lightweight and comfortable. Custom machines can be configured to produce gloves that comply with these regulations while maximizing production speed.

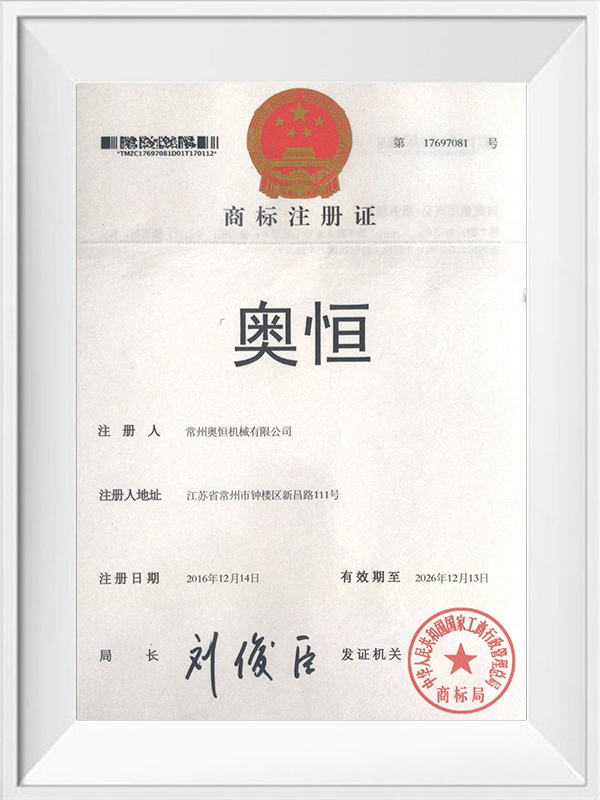

At AOHENG, we specialize in providing disposable product machines that are fully customizable to meet the varied needs of different industries. Our machines integrate cutting-edge technology, such as microcomputer control and full frequency conversion systems, allowing manufacturers to tailor production lines with ease. Furthermore, our glove machines are designed to minimize waste through automatic separation processes, which helps lower labor costs while boosting output. With AOHENG's solutions, manufacturers benefit from durable, efficient, and highly adaptable equipment that enhances production and delivers a competitive edge.

Environmental Considerations in Disposable Products Manufacturing: Reducing Waste with Efficient Machines

As environmental concerns grow, manufacturers of disposable products must focus on reducing waste. Efficient machinery plays a key role in this effort by optimizing material use and minimizing production waste.

How Efficient Machines Reduce Waste

Precise Material Use: Advanced machines control raw material usage, reducing excess and waste.

Automatic Waste Separation: Modern disposable product machines separate waste from finished products, cutting down on manual labor and material loss.

Energy Efficiency: Optimized machines consume less energy, lowering the environmental footprint.

Sustainable Practices

Recycling: Machines that support recycling of waste materials help reduce landfill impact.

Biodegradable Options: Equipment capable of processing biodegradable materials promotes eco-friendly manufacturing.

AOHENG’s Commitment

AOHENG offers customized machines designed for material efficiency and waste reduction. Our glove machines feature automatic waste separation and energy-saving technology, allowing manufacturers to produce high-quality products while minimizing their environmental impact.