Request A Quote

Introduction to Ultrasonic Towel Cutting Machines An ultrasonic towel cutting machine is a specialized piece of equipment used in the textile industry to cut towel fabrics with precision, speed, and m...

View MoreMeeting High Output Demands in Large-Scale Towel Manufacturing Large-scale towel production is driven by continuous orders, fixed delivery schedules, and strict dimensional requirements. Manual or sem...

View MoreBag sealing is a critical process in packaging, ensuring products are protected from contamination, leakage, and spoilage. Two common methods for sealing plastic and laminated bags are ultrasonic seal...

View MoreThe Science Behind Ultrasonic Cutting: Principles and Mechanisms Explained

Ultrasonic cutting technology represents a significant advancement in the field of material processing, utilizing high-frequency sound waves to achieve precise and efficient cutting. At its core, ultrasonic cutting relies on the principles of ultrasonic vibration, which allows for the seamless slitting and cross-cutting of various soft materials, including cloth, non-woven fabrics, paper, and plastic films.

The fundamental principle behind ultrasonic cutting involves an ultrasonic generator that produces high-frequency vibration waves. These waves are converted into mechanical vibrations by a transducer, which is then transmitted to an ultrasonic cutting knife. The knife vibrates at a frequency typically between 20 kHz and 40 kHz. As it contacts the material, the high-frequency vibrations generate localized friction and heat at the cutting surface. This action causes the material to soften and melt in specific areas, allowing the cutting knife to glide through the material with minimal resistance.

This method of cutting has several advantages over traditional cutting techniques. For instance, ultrasonic cutting does not require sharp blades, which reduces wear and tear, minimizing maintenance costs. Additionally, the low pressure exerted on the material during the cutting process helps preserve the integrity of the material, making it especially suitable for soft, viscous, or elastic substances.

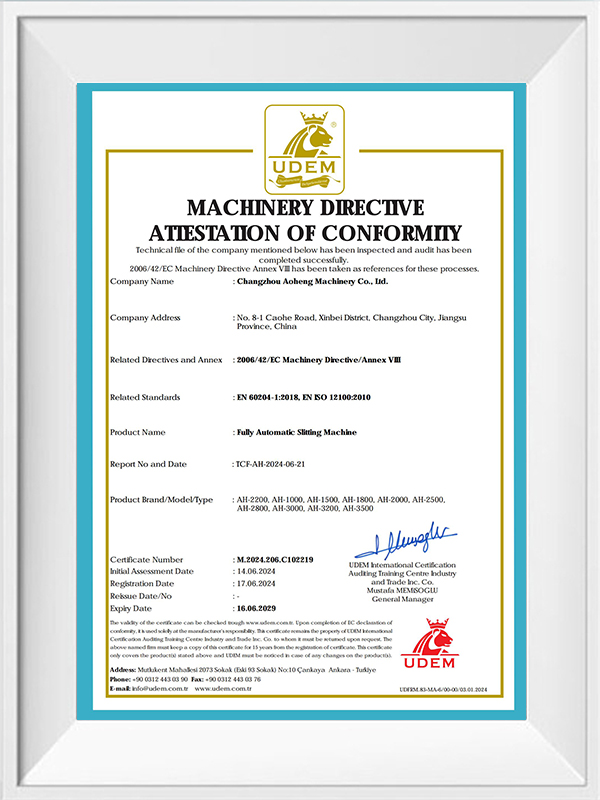

At our manufacturing facility, we specialize in producing high-quality ultrasonic cutting machines that are designed to meet the diverse needs of our clients. Our machines not only embody the latest technological advancements in ultrasonic cutting but also reflect our commitment to quality and reliability. By investing in our ultrasonic slitting machines, you can enhance your production capabilities, reduce operational costs, and achieve exceptional cutting results across various materials.

Case Studies: Successful Implementations of Ultrasonic Slitting in Various Industries

1. Textile Industry: Enhancing Fabric Processing

Consider a textile manufacturer struggling with fabric slitting. Traditional cutting methods often lead to frayed edges and inconsistent cuts, resulting in material waste and increased production costs. By integrating ultrasonic slitting machines into their production line, this hypothetical company could achieve significant improvements. The ultrasonic cutting technology might ensure clean, precise cuts, drastically reducing fabric fraying and enhancing the quality of the final products.

2. Packaging Industry: Streamlining Production

Imagine a leading packaging company facing challenges with its non-woven packaging bag production. The traditional cutting methods employed could be slow and lead to uneven cuts, affecting the integrity of the bags. If this company were to switch to ultrasonic slitting technology, it might experience faster cutting speeds and consistent results. The ultrasonic process could allow for multiple layers of non-woven material to be cut simultaneously, significantly increasing productivity without damaging the material.Our ultrasonic slitting machines could provide this company with the reliability and efficiency needed to streamline production, potentially reducing lead times and boosting customer satisfaction.

3. Medical Industry: Precision and Cleanliness

Visualize a medical manufacturer specializing in surgical drapes and gowns. The need for precision and cleanliness in their cutting processes would be paramount. Traditional cutting methods might pose a contamination risk and require frequent blade replacements, leading to increased downtime. By adopting ultrasonic slitting technology, this manufacturer could cut fabric with minimal contact, thus reducing contamination risks and eliminating the need for sharp blades.