Request A Quote

Content

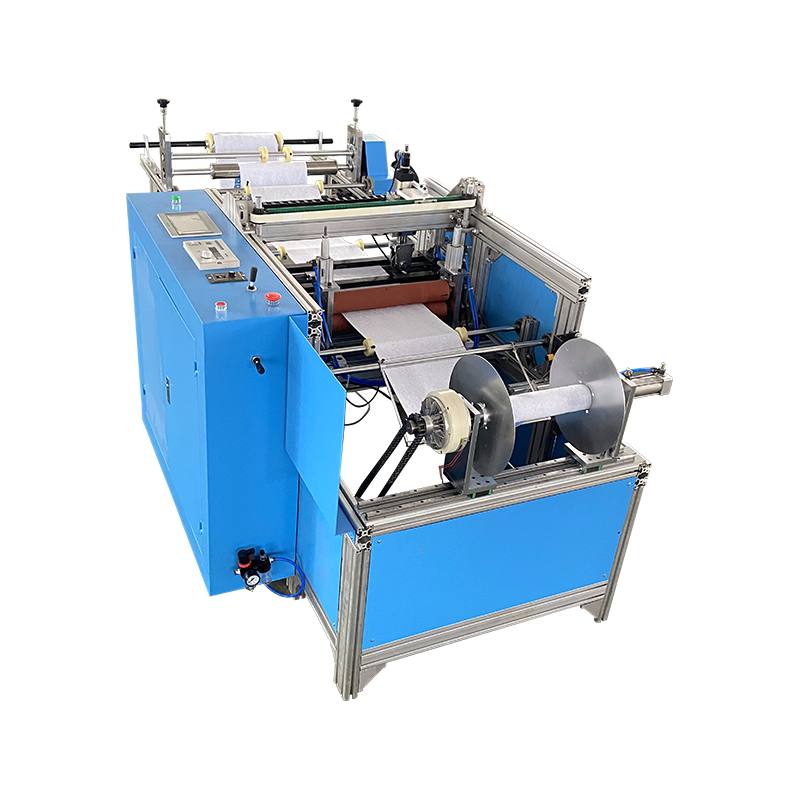

Large-scale towel production is driven by continuous orders, fixed delivery schedules, and strict dimensional requirements. Manual or semi-automatic cutting methods struggle to keep pace with these demands. Automated towel cutting machines are adopted to maintain stable output rates while handling long fabric rolls and high daily production volumes. Their ability to operate continuously with minimal interruption supports mass production environments where consistency and speed are critical.

Dimensional consistency is essential in large-scale production, especially for hotel, retail, and export orders. Automated towel cutting machines rely on programmed length control and synchronized feeding systems to maintain uniform cutting results. This reduces size deviations between batches and supports downstream processes such as hemming, labeling, and packaging without additional adjustments.

Automation replaces manual measurement with digital control systems. Once parameters are set, each towel is cut to the same specification, minimizing cumulative errors that often appear in manual cutting over long production runs.

Large-scale production requires predictable performance across multiple shifts. Automated towel cutting machines reduce reliance on skilled manual operators, limiting variability caused by fatigue or operator turnover. One operator can oversee multiple machines, improving labor efficiency while keeping output stable.

Automated towel cutting machines are designed to balance speed and cutting quality. High-speed blades or synchronized cutting mechanisms allow rapid processing of stacked or continuous fabrics while maintaining clean edges. This capability is particularly important for terry fabrics, where uneven cuts can affect product appearance and finishing efficiency.

Material waste becomes a major cost factor when production volumes are high. Automated towel cutting machines use precise feeding and cutting control to reduce offcuts and length variation. Over long production cycles, even small improvements in material utilization result in measurable cost savings.

In large-scale factories, towel cutting is rarely an isolated process. Automated cutting machines are designed to integrate with upstream fabric inspection and downstream hemming or sewing equipment. This integration supports continuous production flow and reduces handling time between processes.

| Production Aspect | Manual Cutting | Automated Cutting |

| Cutting consistency | Operator dependent | Program controlled |

| Production speed | Limited | High and stable |

Automated towel cutting machines contribute to quality control by reducing variation at the cutting stage. Uniform cut length and clean edges simplify inspection and reduce rejection rates during finishing. This consistency is especially valuable for export-oriented production where quality standards are strictly enforced.

Large-scale towel manufacturing environments prioritize operator safety alongside productivity. Automated cutting machines incorporate guarding, sensors, and controlled cutting zones that reduce direct operator contact with blades. This lowers the risk of injury compared to manual cutting stations handling large fabric volumes.

Although automated towel cutting machines involve higher initial investment, they support long-term cost control in large-scale production. Savings in labor, reduced waste, improved throughput, and stable quality contribute to predictable operating costs. For manufacturers producing towels at scale, automation aligns cutting operations with overall production efficiency goals.

Copyright © ChangZhou AoHeng Machinery Co., Ltd. All Rights Reserved

English

English 中文简体

中文简体 русский

русский Español

Español