Request A Quote

Content

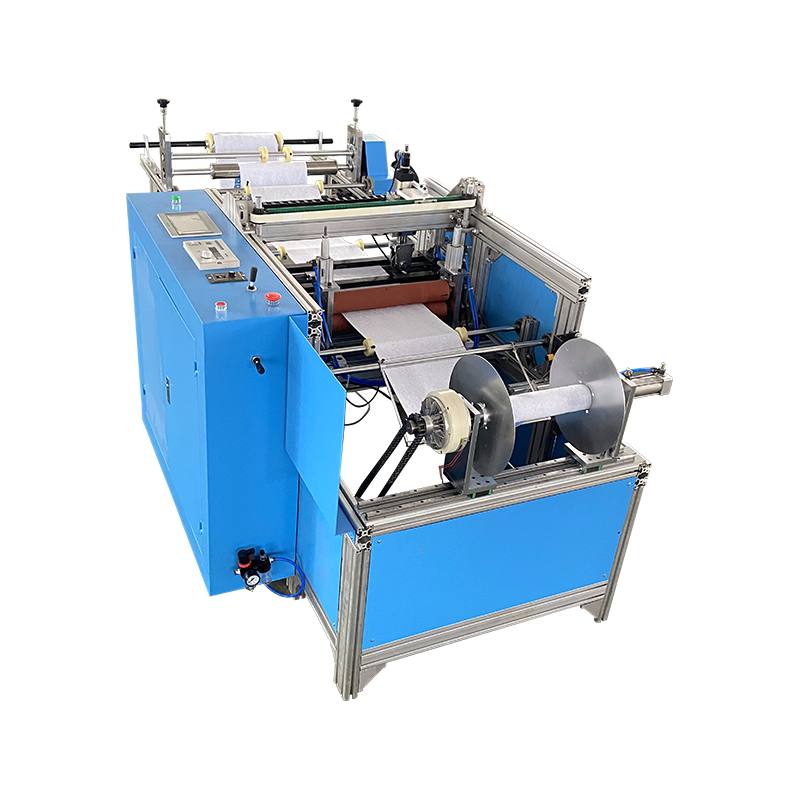

An ultrasonic towel cutting machine is a specialized piece of equipment used in the textile industry to cut towel fabrics with precision, speed, and minimal fraying. Unlike traditional cutting methods that use mechanical blades, ultrasonic cutting employs high-frequency sound waves to heat and melt the fabric fibers at the cutting edge. This results in cleaner cuts, increased cutting speed, and superior edge quality. These machines are particularly beneficial in towel production, where fabric integrity and neat edges are essential.

The process behind ultrasonic towel cutting is based on the principle of converting high-frequency electrical energy into mechanical energy. This is achieved by an ultrasonic transducer, which generates sound waves that are applied to the cutting tool. These sound waves vibrate at a high frequency, which creates frictional heat. When applied to the towel fabric, the heat causes the fibers at the cutting edge to melt, effectively sealing the fabric and preventing fraying.

An ultrasonic towel cutting machine consists of several key components that work together to ensure efficient and precise cutting:

Ultrasonic towel cutting machines offer several significant advantages over traditional mechanical cutting methods, especially in terms of efficiency, product quality, and operational costs.

One of the key benefits of ultrasonic cutting is its ability to seal the edges of the fabric as it cuts, preventing fraying and unraveling of the towel fibers. This is especially important for delicate fabrics or towel materials like terry cloth, where maintaining edge integrity is crucial for both aesthetics and durability.

Ultrasonic towel cutting machines can cut fabric much faster than traditional cutting methods, such as rotary or guillotine cutting. The high-frequency vibrations allow the machine to move through the fabric quickly and cleanly, leading to higher productivity rates and reduced production times.

The precision of ultrasonic cutting ensures that each towel is cut to the exact desired size without jagged edges. This contributes to a more professional appearance and reduces the need for additional finishing work, such as trimming or edge-sealing.

Ultrasonic cutting systems are generally more energy-efficient than traditional mechanical systems because they focus energy precisely where it’s needed—the cutting edge. This reduces waste, lower energy consumption, and extends the life of the machine.

Ultrasonic towel cutting machines are widely used in industries where high-precision fabric cutting is essential. Their ability to provide neat and clean cuts makes them an ideal choice for towel manufacturers and other textile production applications.

When selecting an ultrasonic towel cutting machine, several factors should be taken into account to ensure optimal performance and efficiency:

Ultrasonic towel cutting machines represent a significant advancement in textile cutting technology, offering improved cutting speed, precision, and fabric integrity. These machines are especially valuable in towel manufacturing and other textile applications, where clean edges and efficient production are essential. By utilizing high-frequency sound waves to perform the cutting, ultrasonic machines minimize fraying and maximize productivity, making them a preferred choice for modern textile manufacturers.

Copyright © ChangZhou AoHeng Machinery Co., Ltd. All Rights Reserved

English

English 中文简体

中文简体 русский

русский Español

Español