Request A Quote

Ultrasonic welding achieves bonding by converting high-frequency electrical signals into mechanical vibrations, which are transmitted to the materials being welded. These vibrations, typically in the range of 20 kHz to 40 kHz, generate rapid molecular-level friction at the interface of the fabric layers. This friction produces localized heat, which softens or melts thermoplastic components at the contact points, allowing them to fuse when pressure is applied.

When welding fabrics of varying thicknesses, the process still maintains consistent fusion through several key mechanisms:

Localized Energy Concentration

One of the core advantages of ultrasonic welding is its ability to concentrate energy precisely where the bonding is required. The vibrational energy does not dissipate throughout the fabric but focuses on the interface where the horn contacts the material. This targeted energy transfer ensures that only the immediate contact area undergoes thermal softening, regardless of the total fabric thickness. Therefore, even if the upper layer is thin and the lower one is thicker, the bonding occurs only at the interface where heat is generated most effectively.

Uniform Pressure Application

The ultrasonic welding horn (or sonotrode) and the patterned anvil apply a controlled and evenly distributed pressure across the material layers. This pressure plays a crucial role in maintaining consistent contact between layers, which is essential for the proper transmission of vibrational energy. In scenarios with varying thickness, the machine's pressure system is calibrated to compensate for uneven material distribution, ensuring that energy reaches the intended fusion zone uniformly.

Adaptive Energy Delivery

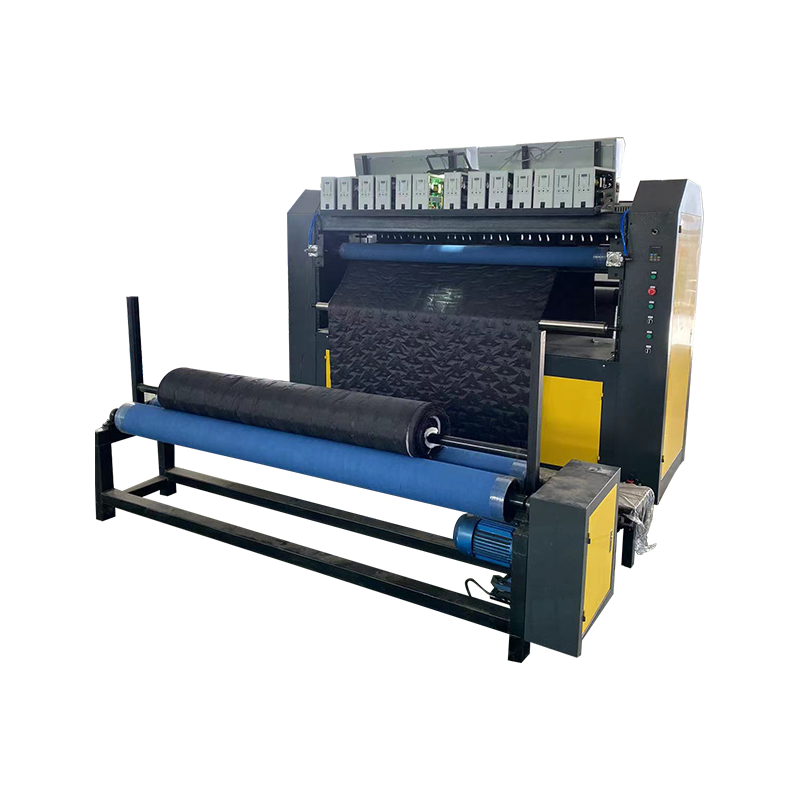

Modern Cross Ultrasonic Quilting Machines are equipped with programmable settings that allow for precise control of amplitude (vibration intensity), duration (weld time), and power output. These parameters can be fine-tuned based on the material’s composition and thickness. For example, a thicker composite fabric may require higher amplitude or longer weld time, while thinner materials may bond effectively with lower energy input. The ability to adapt these parameters ensures that consistent fusion is achieved without damaging delicate layers or under-welding thicker regions.

Thermoplastic Compatibility

The effectiveness of ultrasonic welding largely depends on the thermoplastic properties of the materials involved. Most ultrasonic quilting applications involve fabrics or composite layers that soften or melt at specific temperatures. As long as the materials have similar or compatible melting points, the ultrasonic energy will generate enough heat through molecular friction to bond them uniformly. This compatibility ensures that even if one layer is significantly thicker, the bonding interface behaves predictably during the welding process.

Minimal Thermal Distortion

Unlike conventional heating methods that raise the temperature of the entire material, ultrasonic welding confines the heat generation to a narrow zone. This minimizes the risk of thermal distortion or warping, which is particularly important when dealing with layered materials of different thicknesses. The quick cooling time after the bond is formed also contributes to structural integrity and uniform appearance.

Feedback and Control Systems

Advanced ultrasonic systems often include real-time feedback mechanisms that monitor welding performance, such as energy input, pressure consistency, and bonding time. These systems can detect anomalies in the process—such as incomplete bonding or overheating—and adjust the settings automatically to maintain quality. This ensures that inconsistent fabric thickness does not lead to variable welding results.

Molecular-level friction in ultrasonic welding ensures consistent fusion across fabrics of varying thickness through a combination of localized energy concentration, controlled mechanical pressure, material-specific energy tuning, and real-time process feedback. These features enable the ultrasonic quilting machine to deliver precise, reliable bonding in complex multilayer textile assemblies without compromising the quality or integrity of the final product.

Copyright © ChangZhou AoHeng Machinery Co., Ltd. All Rights Reserved

English

English 中文简体

中文简体 русский

русский Español

Español