Request A Quote

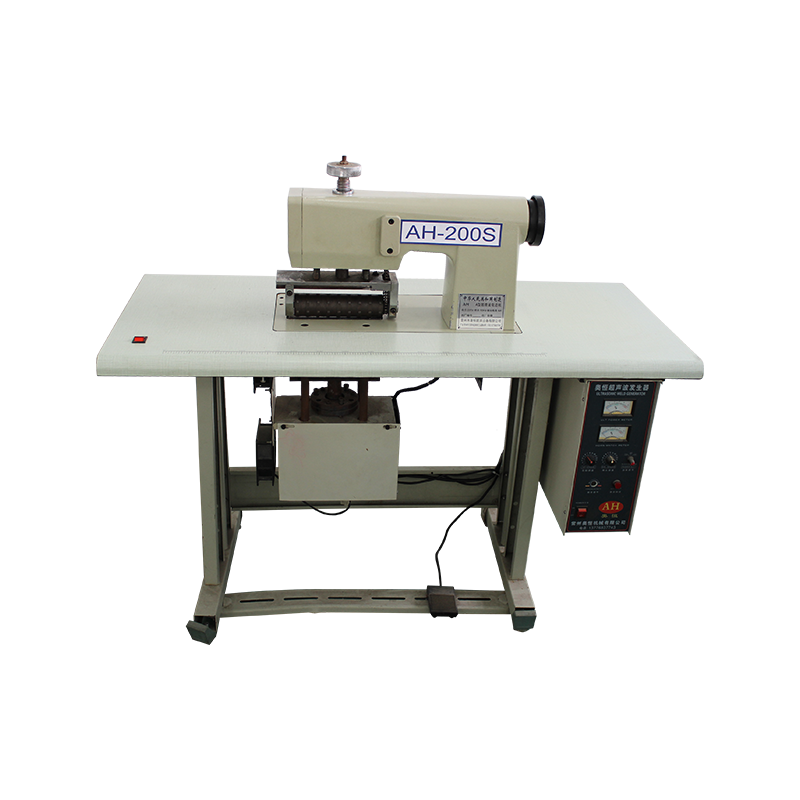

In the evolving landscape of textile and apparel manufacturing, innovation is driven by the need for speed, precision, sustainability, and cost efficiency. Among the most transformative advancements in recent decades is the ultrasonic sewing machine — a technology that redefines how fabrics are joined without the use of traditional needles, threads, or mechanical stitching.

Unlike conventional sewing methods that rely on interlocking thread loops to bind materials together, ultrasonic sewing machines utilize high-frequency vibrational energy to fuse thermoplastic fibers at the molecular level. This process not only eliminates the need for consumables like thread and needles but also enhances seam integrity, reduces production time, and minimizes material waste — all while delivering a clean, durable, and aesthetically refined finish.

This article explores the underlying principles, technological evolution, industrial applications, and future potential of ultrasonic sewing machines, highlighting their growing role in reshaping modern garment and technical textile production.

How Ultrasonic Sewing Works

At the core of ultrasonic sewing technology lies the principle of high-frequency acoustic energy , typically operating between 20 kHz and 40 kHz — beyond the range of human hearing. This energy is converted into mechanical vibrations through a device known as a transducer, which is connected to a sonotrode or sealing bar.

When fabric layers are placed between the sonotrode and an anvil, the vibrations generate localized frictional heat within the material. In thermoplastic-based textiles such as polyester, nylon, polypropylene, or blends containing these polymers, this heat causes the fibers to soften and momentarily melt. Under applied pressure, the softened fibers bond together, forming a continuous, seamless joint as they cool and solidify.

This entire process occurs in a matter of seconds and can be precisely controlled to achieve varying seam widths, thicknesses, and bonding strengths depending on the application.

Advantages Over Traditional Sewing Methods

The shift from mechanical to ultrasonic sewing brings with it a host of operational and qualitative benefits:

No Thread Required : Eliminates dependency on spools, needles, and tension adjustments, reducing maintenance and downtime.

Faster Production Speeds : Seaming rates can exceed those of traditional sewing machines due to the absence of threading and looping mechanisms.

Clean, Seamless Edges : Produces smooth, fray-resistant seams ideal for performance wear, medical textiles, and disposable garments.

Enhanced Seam Strength : Bonds created through ultrasonic welding often exhibit superior tensile strength compared to stitched seams, particularly in synthetic fabrics.

Reduced Material Waste : Precision bonding allows for tighter seam allowances, maximizing fabric utilization.

Improved Hygiene and Safety : Especially beneficial in sterile environments like healthcare and cleanroom manufacturing, where loose threads or lint are unacceptable.

These advantages make ultrasonic sewing particularly well-suited for industries where durability, cleanliness, and aesthetic refinement are paramount.

Applications Across Industries

Ultrasonic sewing machines have found a wide range of applications across multiple sectors, each benefiting from the unique properties of ultrasonic bonding:

1. Apparel Manufacturing

Used extensively in sportswear, swimwear, and activewear production, where stretchable, flexible seams are essential. Brands leverage this technology to create garments that move with the body without chafing or fraying.

2. Medical and Protective Wear

Integral in the production of surgical gowns, masks, gloves, and isolation suits, where sterility and seam integrity are critical. Ultrasonic bonding ensures leak-proof seals and prevents fiber shedding.

3. Disposable Products

Commonly used in the assembly of diapers, sanitary products, and adult incontinence wear, where elastic attachment and waterproof sealing are required.

4. Technical Textiles

Applied in the manufacture of airbags, filtration membranes, geotextiles, and composite reinforcements, where high-strength, consistent bonds are necessary.

5. Automotive Interiors

Utilized to join seat covers, headliners, and interior trim components made from synthetic nonwovens and coated fabrics.

Each of these applications demonstrates the adaptability of ultrasonic sewing in meeting diverse functional and aesthetic demands.

Integration with Smart Manufacturing and Automation

As the textile industry embraces Industry 4.0 and digital manufacturing, ultrasonic sewing machines are increasingly being integrated into automated workflows and intelligent control systems. These include:

Programmable Bonding Parameters : Operators can adjust frequency, pressure, and dwell time via touchscreen interfaces to tailor seams to specific fabric types and thicknesses.

Integration with CAD/CAM Systems : Allows for direct translation of digital patterns into physical seams with minimal manual intervention.

Real-Time Quality Monitoring : Sensors embedded in the machine detect inconsistencies in bonding strength or seam width, enabling immediate corrective action.

Robotics-Assisted Handling : Paired with robotic arms, ultrasonic sewing units can perform complex joining operations on curved or three-dimensional surfaces.

Such integration not only improves repeatability and consistency but also supports mass customization — a growing trend in fashion and technical textiles alike.

Sustainability and Environmental Impact

One of the most compelling aspects of ultrasonic sewing is its alignment with sustainable manufacturing practices:

Elimination of Thread and Needles : Reduces reliance on petroleum-based threads and decreases waste associated with needle disposal.

Lower Energy Consumption : Compared to traditional sewing lines, ultrasonic machines consume less power per unit output due to shorter cycle times and fewer moving parts.

Material Efficiency : Tighter seam construction means less fabric is needed per garment, contributing to reduced overproduction and textile waste.

Recyclability : Since ultrasonically bonded seams do not contain foreign materials like thread, they facilitate easier recycling of post-consumer garments.

These environmental benefits position ultrasonic sewing as a key enabler of eco-conscious production strategies, especially as brands seek to reduce their carbon footprint and comply with stricter regulations.

Challenges and Considerations

Despite its many advantages, ultrasonic sewing is not universally applicable. Certain limitations must be taken into account when adopting this technology:

Material Compatibility : Only thermoplastic or heat-reactive fibers respond well to ultrasonic bonding. Natural fibers like cotton or wool require blending with synthetic materials to achieve effective welds.

Initial Investment Cost : High-performance ultrasonic sewing machines can be more expensive than traditional sewing equipment, though long-term savings often justify the expense.

Operator Training : Requires skilled personnel who understand the interaction between material properties, machine settings, and bonding outcomes.

Noise Levels : Although generally safe, some ultrasonic machines emit high-pitched sounds that may necessitate soundproofing or protective gear in large-scale facilities.

Manufacturers must carefully evaluate these factors to determine whether ultrasonic sewing aligns with their production goals and material specifications.

Future Developments and Emerging Trends

Looking ahead, several innovations are poised to further expand the capabilities of ultrasonic sewing technology:

Multi-Layer Bonding : Research into simultaneous bonding of multiple fabric layers to enhance structural complexity and functionality.

Hybrid Systems : Combining ultrasonic bonding with laser cutting or embroidery for multi-process integration in a single workstation.

Biodegradable Polymer Integration : Development of bio-based thermoplastics compatible with ultrasonic welding to support circular economy initiatives.

Wearable Electronics Integration : Exploring ways to embed conductive fibers or sensors directly into ultrasonically bonded seams for smart clothing applications.

These advancements reflect a broader movement toward smarter, cleaner, and more adaptable textile manufacturing — one in which ultrasonic sewing plays a central and evolving role.

Copyright © ChangZhou AoHeng Machinery Co., Ltd. All Rights Reserved

English

English 中文简体

中文简体 русский

русский Español

Español