Request A Quote

In the textile industry, towel cutting machines are vital equipment that directly influence the efficiency, precision, and overall quality of towel production. From small workshops to large scale factories, manufacturers use a range of cutting technologies to meet their production goals. The type of towel cutting machine selected often depends on factors such as production capacity, fabric thickness, accuracy requirements, and the level of automation desired. By understanding the common types of towel cutting machines, manufacturers can make informed choices that improve workflow and product quality.

The most basic option is the manual cutting machine. These machines are often table mounted or handheld and are mainly used in small production units where demand is limited or in cases where custom towel sizes are required. Manual cutting requires skilled operators who can measure and cut each piece individually. While the investment cost is relatively low, this method is labor intensive and not suitable for mass production. In addition, manual cutting often results in variations in size and less consistent quality, which is a disadvantage in a highly competitive textile market. However, for workshops focusing on personalized towels or small orders, manual cutting machines still play an important role.

Rotary blade cutting machines are a step forward in terms of efficiency and speed. These machines use circular blades that move rapidly to cut large rolls of fabric into uniform towel sized pieces. Because of their design, rotary machines are particularly effective for straight cuts and repetitive tasks. They are widely used in medium to large textile factories where higher production output is required. Their main strengths lie in their ability to cut quickly and consistently, significantly reducing labor costs and production time compared to manual cutting. However, rotary systems may have limitations when it comes to cutting complex shapes or very thick fabric stacks.

Band knife cutting machines provide greater flexibility than rotary blade systems. The continuous loop blade allows them to cut through multiple layers of fabric at once, which is particularly valuable when handling thick or heavy towel materials. The band knife design also makes it possible to cut curves or more intricate shapes, offering versatility beyond straight line cutting. These machines are often used in larger manufacturing setups where both efficiency and adaptability are important. Although they require more maintenance and operator training compared to rotary machines, their ability to handle complex tasks makes them a valuable option.

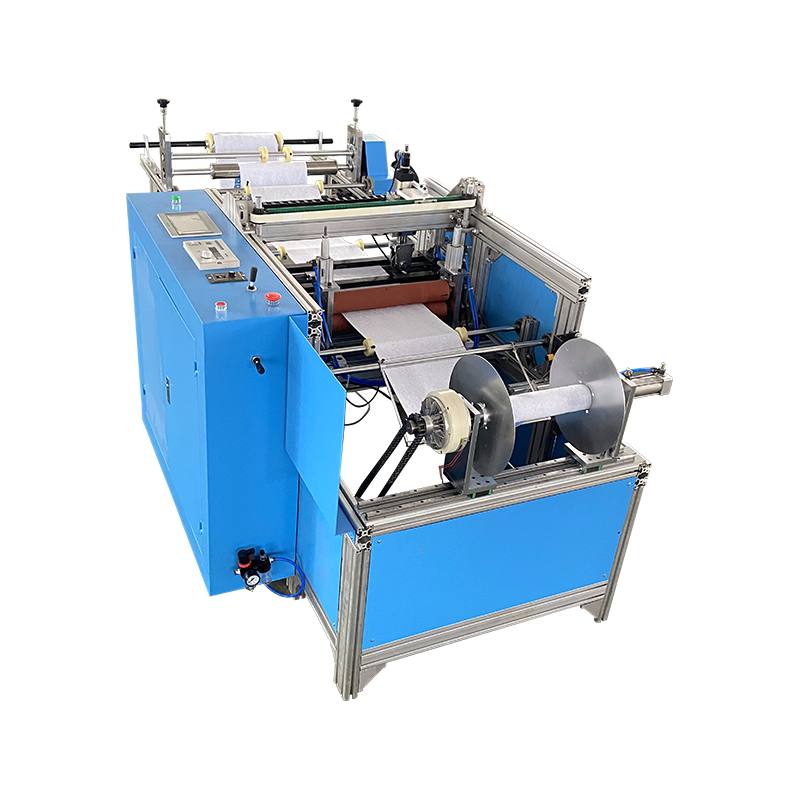

In large scale production, automatic roll to piece cutting machines are among the most commonly used. These machines combine speed, precision, and automation by feeding fabric rolls, measuring exact dimensions, and cutting towels automatically. They are often integrated into production lines with conveyors and stacking systems, creating a smooth flow of material from cutting to the next stage of manufacturing. This type of machine reduces human involvement, which not only lowers labor costs but also minimizes errors. For factories that produce towels in large quantities, automatic cutting machines are essential because they maintain consistent product quality while meeting high volume demands.

For premium towel production or customized designs, laser cutting machines are sometimes applied. By using focused laser beams, these machines cut towels with extreme accuracy and can create decorative patterns, logos, or special shapes that are difficult to achieve with mechanical blades. One of the advantages of laser cutting is that the edges are sealed during the process, which prevents fraying. However, the high cost of investment and slower cutting speed compared to mechanical systems limit their use in mass production. They are more suitable for niche markets where customization and design quality are more important than speed.

Ultrasonic cutting machines represent another advanced option in textile cutting. These machines use high frequency vibrations to cut through fabric while simultaneously sealing the edges. This dual function ensures that the towels maintain clean, smooth edges that do not unravel during use. Ultrasonic cutting is especially beneficial when working with delicate fabrics that require precise handling. Although not as widely used as rotary or automatic roll to piece machines, ultrasonic systems are gaining attention in markets where quality finishing and durability are priorities.

Die cutting machines are particularly useful when producing towels in large batches with uniform sizes and shapes. These machines use metal dies, similar to molds, that stamp the fabric into predetermined dimensions. This method ensures consistency across every piece, making it highly efficient for standardized production. The main limitation is that die cutting is less flexible since new dies must be created for different towel sizes or designs. Despite this, they remain popular in large scale manufacturing where standardization is more important than versatility.

When comparing these different types, it becomes clear that each machine serves a distinct purpose. Manual machines are best for small orders and custom work, rotary blades for straightforward high speed cutting, band knives for flexibility and thicker fabrics, automatic roll to piece machines for mass production, and laser or ultrasonic systems for premium and specialized markets. Die cutting machines occupy a unique position, excelling in standardized mass production.

In practice, most large factories rely heavily on rotary blade and automatic roll to piece cutting machines because they provide the best balance of speed, efficiency, and cost effectiveness. Specialized technologies such as laser and ultrasonic systems are applied in cases where higher precision and design flexibility are required. Smaller workshops often continue to use manual and band knife machines due to their affordability and adaptability.

By understanding the strengths and limitations of each type of towel cutting machine, textile manufacturers can select the most suitable equipment for their operations. This not only improves production efficiency but also helps maintain consistent quality, reduce waste, and meet the diverse demands of the global towel market.

Copyright © ChangZhou AoHeng Machinery Co., Ltd. All Rights Reserved

English

English 中文简体

中文简体 русский

русский Español

Español