Request A Quote

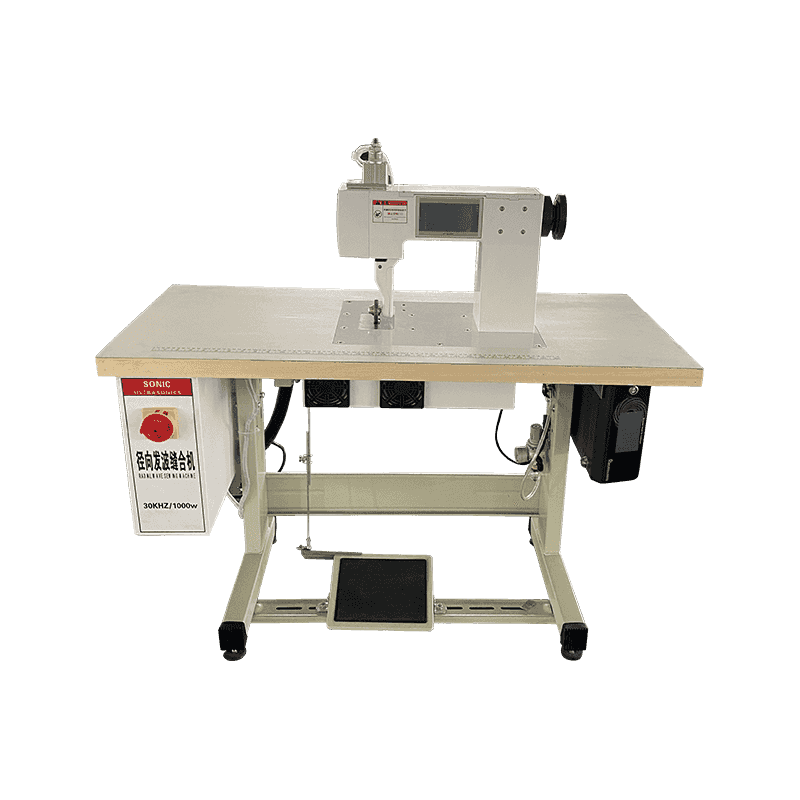

An ultrasonic sewing machine represents a cutting-edge advancement in textile manufacturing, utilizing high-frequency sound waves to join materials together without the need for traditional threads, needles, or stitching. This technology provides a unique, efficient, and highly versatile method for bonding materials, offering several advantages over conventional sewing methods. In this article, we will explore the purpose of ultrasonic sewing machines, how they work, and their key applications across various industries.

Content

The ultrasonic sewing machine operates by generating high-frequency sound waves, typically in the range of 20 kHz to 40 kHz. These sound waves are passed through the material, creating rapid microscopic vibrations at the point of contact. The friction generated by these vibrations produces heat, which causes the materials to bond together at a molecular level. This process, often referred to as "ultrasonic welding" or "ultrasonic bonding," allows the materials to fuse without the need for any threads, adhesives, or other fastening methods.

In an ultrasonic sewing machine, the high-frequency sound waves are directed into the fabric through a specially designed tool called a "sonotrode" or "horn," which applies pressure to the material. The energy from the sound waves creates heat, melting the fibers at the point of contact and causing them to bond securely. Once the material cools, the bond is strong and durable, and the seam is formed without any visible stitching.

Seam Bonding Without Thread or Needles

One of the most significant advantages of an ultrasonic sewing machine is its ability to bond fabrics or materials without using traditional sewing threads. This eliminates the need for needles, stitching, and thread, allowing for a more efficient and streamlined manufacturing process. The ultrasonic process creates seams by fusing the materials at the molecular level, providing a strong and durable bond without the risk of thread breakage or damage to delicate fabrics.

Speed and Efficiency

Ultrasonic sewing machines operate faster than conventional sewing machines. The absence of threading, needling, and manual adjustments reduces setup times and speeds up the entire process. As a result, production times are significantly reduced, which can be particularly beneficial in industries where high-volume production is required, such as automotive manufacturing or fashion production.

Precision and Cleanliness

Ultrasonic welding provides precise control over the bonding process, ensuring that the seams are perfectly aligned and consistently strong. The process results in smooth, clean seams with no visible stitching, fraying, or imperfections. This is particularly valuable in applications where the aesthetic appearance of the product is crucial, such as in high-end fashion garments or medical products.

Material Versatility

Ultrasonic sewing machines can bond a wide range of materials, including thermoplastic fabrics, nonwoven fabrics, and even multi-layer composite materials. This versatility allows manufacturers to use ultrasonic technology to join materials that are typically difficult to sew using traditional methods, such as thick synthetic fabrics, films, and nonwovens. This makes it an invaluable tool in a variety of industries, from medical device production to automotive manufacturing.

No Additional Materials Needed

One of the standout features of ultrasonic sewing is that no additional materials, such as thread or adhesive, are required. The process uses only the materials being welded, which helps to reduce production costs and material waste. Furthermore, the absence of thread means there is no risk of thread breakage or unraveling over time, ensuring a more reliable and durable bond.

Medical Industry:

Ultrasonic sewing machines are widely used in the medical industry to create sterile, secure seams in products like disposable gowns, surgical drapes, face masks, and sterile packaging. The ability to join materials without using thread or needles reduces the risk of contamination and ensures that the seams remain intact even after exposure to harsh medical environments. Additionally, ultrasonic welding allows for precise control over the seam, ensuring the highest level of safety and hygiene.

Textile and Fashion:

In the fashion and textile industries, ultrasonic sewing machines are used to create seamless garments and advanced designs in fabrics like sportswear, lingerie, and outerwear. These machines are particularly useful for producing garments where traditional stitching might cause discomfort or create visible seams. For example, ultrasonic sewing is used to create smooth, invisible seams in high-performance sports clothing or compression garments, which require both flexibility and durability.

Automotive Industry:

Ultrasonic welding plays a vital role in the automotive industry, where it is used to bond fabrics for seat covers, airbags, upholstery, and other automotive components. The strong, durable seams created by ultrasonic welding can withstand the extreme conditions found in vehicles, such as high temperatures, vibrations, and stress. Additionally, the speed and precision of ultrasonic welding make it an ideal solution for high-volume manufacturing in automotive production lines.

Packaging and Nonwoven Fabrics:

Ultrasonic sewing machines are also widely used in the production of nonwoven fabrics and packaging materials. In industries like disposable hygiene products (e.g., diapers, wipes), ultrasonic welding helps to create secure, hygienic seams without the need for adhesives or thread. The clean, precise bonding process ensures that products like diapers and medical drapes remain sterile and effective without the risk of material degradation over time.

Electronics and Soft Robotics:

Ultrasonic sewing technology is finding applications in the electronics and robotics fields, particularly in the production of soft robotic components or flexible electronic materials. The ability to bond thin, delicate materials without the use of needles or adhesives allows for the creation of lightweight, flexible, and durable components that can be used in soft robotics, wearables, and other advanced electronic devices.

No Thread or Needles:

One of the most significant benefits of ultrasonic sewing is that it eliminates the need for threads or needles, making the process faster and more efficient. This feature also reduces the risk of fabric damage caused by puncturing or threading.

Clean and Strong Joints:

Ultrasonic welding creates smooth, strong joints that are free from thread breakage, fraying, or other common stitching problems. This results in a high-quality, durable product that can withstand wear and tear over time.

Environmental and Cost Benefits:

By eliminating the need for thread and adhesives, ultrasonic welding reduces material waste, which can have significant environmental and cost benefits. The lack of additional consumables also means lower production costs in the long run.

Increased Speed and Productivity:

The ultrasonic process is fast and efficient, reducing production time and increasing overall productivity. This is especially valuable in industries that require high-volume, rapid manufacturing.

Ultrasonic sewing machines are revolutionizing the way fabrics and materials are joined together, offering a cleaner, faster, and more efficient method than traditional sewing techniques. By using high-frequency sound waves to bond materials at a molecular level, ultrasonic machines provide strong, durable, and precise seams without the need for thread, needles, or adhesives. This technology is especially valuable in industries where hygiene, precision, and speed are critical, such as medical device production, automotive manufacturing, fashion, and packaging. As manufacturing processes continue to evolve, ultrasonic sewing machines will play an increasingly important role in shaping the future of material bonding.

Copyright © ChangZhou AoHeng Machinery Co., Ltd. All Rights Reserved

English

English 中文简体

中文简体 русский

русский Español

Español