Request A Quote

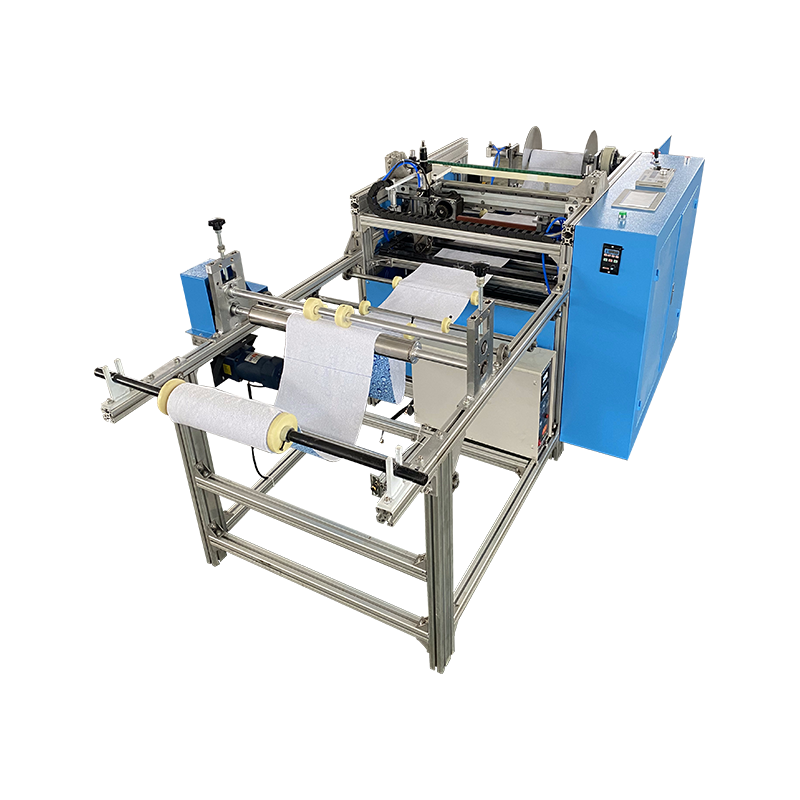

A towel cutting machine is a specialized piece of textile equipment used to cut bulk fabric—typically terry cloth, microfiber, or cotton—into individual towels of predetermined sizes. It plays a critical role in the post-weaving stage of towel manufacturing, ensuring that each towel is accurately shaped, uniformly sized, and ready for further finishing steps such as hemming, labeling, or packaging.

This machine streamlines production by replacing manual cutting, improving both speed and consistency across large production batches.

1. Purpose and Importance in Towel Manufacturing

In commercial towel production, fabrics are usually woven in large rolls or sheets. These wide panels must then be cut into multiple towel pieces (e.g., bath towels, hand towels, washcloths) of specific dimensions. A towel cutting machine automates this process, saving time and minimizing material waste.

The main objectives of the machine are:

Precision cutting to exact dimensions

Clean, uniform edges to simplify sewing or hemming

High output to meet industrial production demands

2. Basic Working Principle

A towel cutting machine typically operates as part of a continuous or semi-continuous textile line. The process generally includes the following steps:

Fabric Feeding: Rolled or stacked towel fabric is fed into the machine manually or via an automatic unwinding system.

Alignment and Tension Control: The fabric is aligned using tension rollers and guide systems to ensure even feeding and prevent distortion.

Measurement: Built-in sensors or programmable logic controllers (PLC) are used to measure the length and width for each cut, ensuring precision.

Cutting Operation: Blades—either rotary or guillotine-style—cut the fabric to the desired size. Some machines allow simultaneous cutting of multiple layers.

Discharge: The cut towel pieces are collected on a conveyor belt or stacking unit, ready for stitching or other finishing processes.

Advanced machines may also feature automatic edge trimming, multi-size programming, or pattern detection for printed or embroidered towels.

3. Types of Towel Cutting Machines

There are different types of machines used in towel cutting, depending on production volume, fabric type, and the level of automation required:

Manual or Semi-Automatic Cutting Tables: Used in small-scale operations, where the fabric is measured and cut manually or with mechanical assistance.

Fully Automatic Towel Cutting Machines: Designed for high-speed production, equipped with computerized control systems, automatic feeders, and precision blades.

Ultrasonic or Heat-Based Cutters: For synthetic towels (like microfiber), which need sealed edges to prevent fraying.

Slitting Machines: Sometimes used in conjunction with towel cutters to divide wider fabrics before final cutting.

4. Integration with Other Processes

Towel cutting machines are often part of a larger production line that may include:

Edge folding and hemming machines

Labeling or tagging units

Stacking and counting systems

Packaging stations

Integrating the cutting machine with these components improves production flow and reduces manual handling.

5. Benefits of Using a Towel Cutting Machine

Improved Efficiency: Reduces cutting time significantly compared to manual methods.

Consistent Quality: Ensures uniform size and edge alignment across large batches.

Material Optimization: Reduces waste through accurate measuring and minimal offcuts.

Labor Savings: Lowers dependence on manual labor, especially for high-volume runs.

Adaptability: Many machines can be programmed for different towel sizes and materials.

Conclusion

A towel cutting machine is a key piece of equipment in the textile industry, particularly in large-scale towel production. It ensures precise, efficient, and high-speed cutting of towel fabric into standardized sizes, ready for finishing and distribution. By automating a traditionally labor-intensive task, it enhances production accuracy, reduces waste, and supports scalable manufacturing. Whether used in small workshops or industrial towel factories, this machine is essential for maintaining quality and productivity in modern textile operations.

Copyright © ChangZhou AoHeng Machinery Co., Ltd. All Rights Reserved

English

English 中文简体

中文简体 русский

русский Español

Español