Request A Quote

Slitting machines are essential equipment in modern manufacturing, designed to cut wide rolls of material into narrower strips with precision and efficiency. These machines are widely applied in industries such as packaging, paper, film, foil, textiles, and metals, where accurate slitting ensures both product quality and process optimization. Understanding the main types of slitting machines is important for selecting the right equipment to match production requirements.

Content

Razor slitting machines use sharp, replaceable blades to cut materials. This method is particularly effective for thin, flexible films such as plastics, foils, and laminates. Razor slitting offers clean edges at high speeds, but it is not suitable for thicker or tougher materials since the blades wear quickly. The simplicity of the system makes it cost-effective and easy to maintain.

Shear slitting operates much like a pair of scissors, with rotating circular knives working against each other. This type is ideal for processing paper, cardboard, nonwoven fabrics, and metals. Shear slitting produces precise, burr-free edges and is often chosen when high cut quality is required. Adjustable knife positions also make it flexible for different widths.

In score slitting, a dull knife presses the material against a hardened roller to create a controlled tear. This method is widely used for materials such as pressure-sensitive adhesives, foams, and corrugated products. Score slitting is less precise compared to shear or razor slitting but effective for difficult-to-cut substrates that might damage standard blades.

Also called roll slitting machines, these cut material by unwinding and rewinding the roll while a blade trims it to the required width. Lathe slitters are often used for large-diameter rolls of tapes, foams, and films. They provide flexibility in handling different material types and allow precise customization of roll widths.

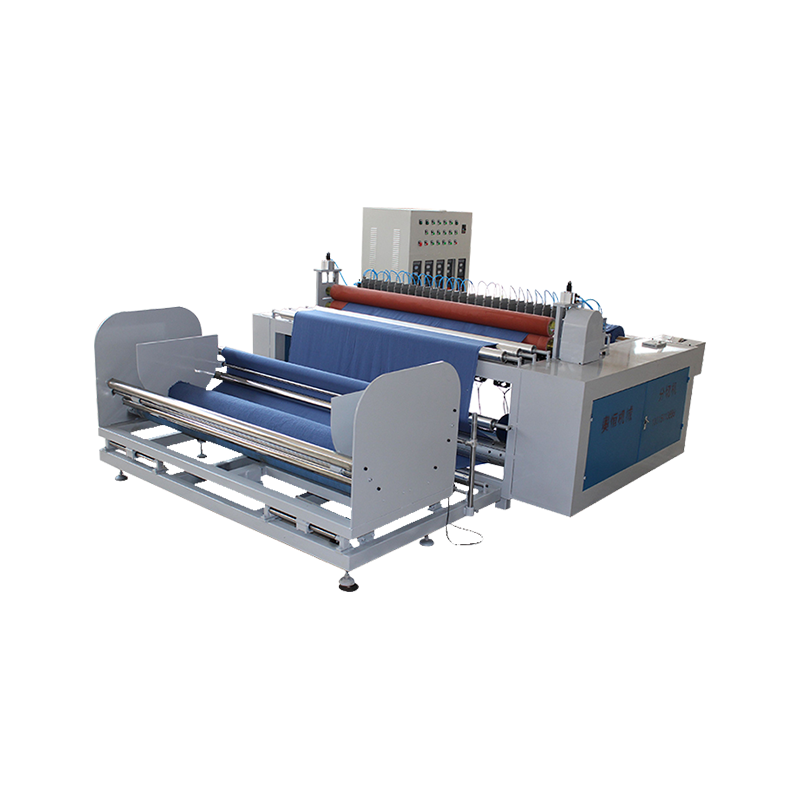

Rewind slitters combine slitting with rewinding. The parent roll is cut into narrower strips, which are then rewound onto separate cores. This method is highly efficient for flexible packaging, plastic films, paper, and foil. It ensures uniform roll tension and alignment, making it a common choice in high-volume production lines.

With the advancement of automation, modern slitting machines are equipped with servo motors, PLC systems, and advanced sensors. These machines automatically control blade positioning, tension, and roll alignment, reducing manual intervention and increasing production accuracy. Automatic slitters are widely used in industries where high precision, speed, and consistency are critical.

In the steel, aluminum, and copper industries, heavy-duty slitting lines are designed specifically for metal coils. These machines feature robust blades, tension control systems, and recoilers to handle the demands of cutting thick or hard materials. Metal slitting machines are vital in construction, automotive, and electrical industries where precision in coil cutting directly impacts downstream processing.

The main types of slitting machines—razor, shear, score, lathe, rewind, automatic, and specialized metal slitters—each serve different industrial needs. The choice depends on material type, thickness, required edge quality, and production volume. By matching the machine to the application, manufacturers can improve efficiency, reduce waste, and achieve higher-quality output in their slitting operations.

Copyright © ChangZhou AoHeng Machinery Co., Ltd. All Rights Reserved

English

English 中文简体

中文简体 русский

русский Español

Español