Request A Quote

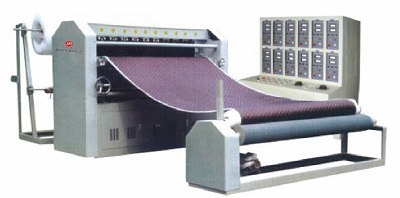

In today’s textile and nonwoven fabric processing industries, operational efficiency, space-saving design, and material optimization are more important than ever. The Ultrasonic Laminating Slitting and Cross-Cutting Machine (Model: AH-1000-3500) is a fully automated, multi-functional system that integrates laminating, slitting, and cross-cutting operations into a single streamlined machine. Compared to using separate machines, this integrated solution significantly reduces manual handling, material waste, and operational costs, while substantially improving productivity.

Key Parameters

| Specification | Details |

| Product Name | Ultrasonic Laminating Slitting and Cross-Cutting Machine |

| Model | AH-1000-3500 |

| Power Supply | 380V |

| Generator Power | 800W × multiple sets (configurable for slitting and lamination) |

| Output Frequency | 20 KHz |

| Operating Speed | 1–20 m/min |

| Slitting Width | Adjustable |

| Max Unwinding Diameter | 1000 mm |

| Knife Configuration | Single or multiple blades (customizable) |

| Drive System | Fully automatic |

| Motors | 3500W servo motor (1 unit), 60N stepper motor (1 unit), 2.2KW transmission motor |

| Inverters | 2 sets (independent for slitting/cutting and lamination) |

| Air Conditioners | 2 units for lamination section |

| Cutter Motor | 8.5N (multiple units) |

| Flower Roller Diameter | 136–230 mm |

| Machine Weight | 2800–3500 kg |

Workflow Overview

The entire machine workflow is logically designed for seamless operation:

Unwinding → Pedal System → Lamination → Ultrasonic Control Cabinet → Pedal + Adjustable Roller → Slitting → Pedal System → Cross-Cutting → Final Output

Product Features

One-Step Integration: The system integrates lamination and slitting/cross-cutting in a single workflow, reducing labor input and material transfer operations.

Automation & Control: Controlled by a centralized PLC system, the machine performs all key processes automatically, increasing consistency and reducing human error.

Advanced Unwinding Design: Dual cradle-style unwinding racks use split-drum conveying and shaft alignment to ensure smooth feeding. Adjustable side barriers accommodate materials of varying widths.

Precision Feeding & Correction: The upper and lower material feeding systems feature automatic edge alignment for consistent feeding with minimal deviation, resulting in clean and uniform cuts.

Adjustable Cutting Systems: Slitting is performed via rail-guided sliding cutters, allowing stable and easy size adjustments. Cross-cutting is high-speed and highly accurate, producing clean, burr-free fabric edges.

High Efficiency Multi-Blade Options: Multiple slitting blades can be added according to production requirements, enhancing throughput and meeting diverse client demands.

Sturdy Mechanical Structure: The rigid framework ensures long-term stability during high-speed operation, boosting machine durability and lifespan.

Customizable Designs: The machine supports a wide variety of patterns and specifications and can be customized to meet unique production requirements.

Application Scope

This multi-functional system is suitable for a wide range of synthetic and nonwoven materials, including:

Chemical fiber fabrics

Microfiber materials

Nonwoven textiles

Spray-bonded cotton

Typical End Products:

Mop cloth

Cleaning rags

Table mats

Disposable handkerchiefs

Disposable bed sheets

Quilt insulation layers (space quilts), and more

Comparison with Standalone Machines

Let’s briefly examine how this integrated system compares to traditional standalone machines:

| Machine Type | Workflow Structure |

| Laminating Machine Only | Multi-layer Unwinding → Laminating Host → Rewinding → Control Cabinet |

| Slitting & Cross-Cutting Machine Only | Unwinding → Pedal System → Slitting → Pedal Roller → Cross-Cutting |

| Integrated System (AH-1000-3500) | Double-layer or multi-layer Unwinding → Laminating → Control Cabinet → Slitting → Cross-Cutting |

Why Integration Matters:

When the integrated machine is separated into two independent systems, each part must include additional components like extra pedals or motors, which increases both equipment cost and space requirements. The integrated design not only lowers the total investment cost but also reduces floor space and labor, while minimizing material handling losses. However, it’s worth noting that not all products or customer requirements are suitable for an integrated system. In some specific cases, separate machines may still be preferred for specialized operations or flexibility.

Conclusion

The Ultrasonic Laminating Slitting and Cross-Cutting Machine represents a modern, efficient, and compact solution for textile processing plants looking to enhance productivity and reduce waste. With its fully automated control system, customizable design, and robust construction, it offers manufacturers a powerful tool to streamline operations while maintaining high product quality. For businesses processing nonwoven or laminated materials, this machine presents a compelling choice for both cost-efficiency and performance.

Copyright © ChangZhou AoHeng Machinery Co., Ltd. All Rights Reserved

English

English 中文简体

中文简体 русский

русский Español

Español