Request A Quote

Content

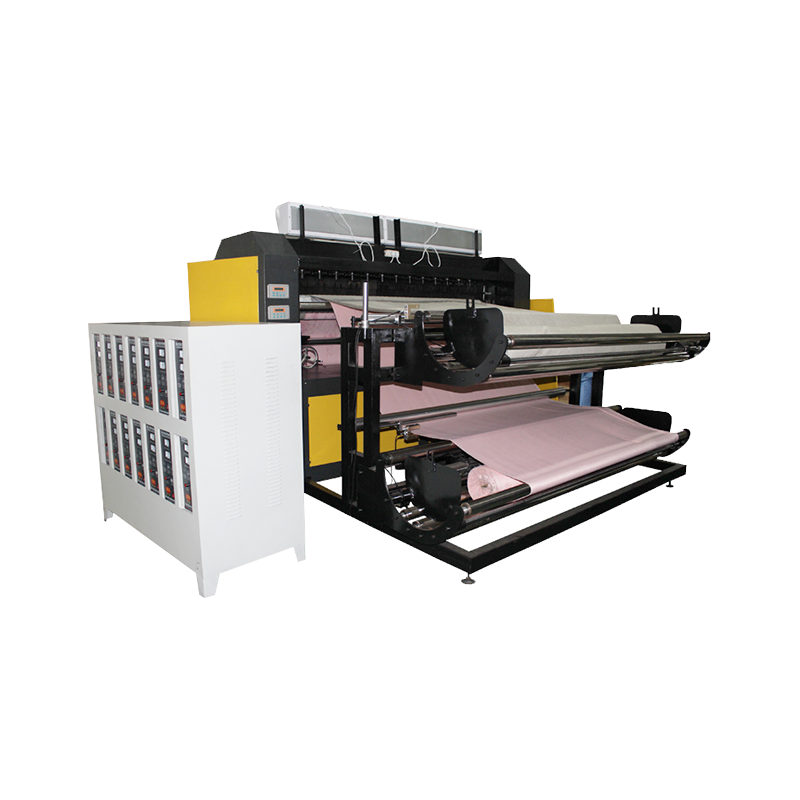

Ultrasonic quilting machines bond fabrics through high-frequency mechanical vibrations instead of traditional sewing threads or glues. The ultrasonic system generates vibrations, usually around 20 to 35 kHz, which are transmitted through the horn (sonotrode) to the fabric layers. The localized vibration causes the molecules at the fabric contact points to rapidly heat and fuse due to frictional energy. Once cooled, the material forms a solid bond, resulting in a seamless quilted joint without any stitching marks or adhesive residues.

The performance and bonding quality of an ultrasonic quilting machine rely on several essential components working in coordination to convert electrical energy into mechanical vibration and apply it effectively to the fabric.

| Component | Function |

| Ultrasonic Generator | Converts electrical energy into high-frequency signals to drive the transducer. |

| Transducer | Transforms electrical signals into mechanical vibrations. |

| Booster | Amplifies the vibration amplitude for efficient energy transfer. |

| Horn (Sonotrode) | Applies ultrasonic energy directly to the fabric layers at precise points. |

| Pattern Roller | Shapes the quilted design and controls the bonding pressure. |

When the horn presses the fabrics against the anvil roller, ultrasonic energy generates rapid frictional heat at the contact surface. This heat causes the thermoplastic fibers within the fabric—such as polyester, nylon, or polypropylene—to reach their softening point. The molecular chains temporarily loosen and intermingle between layers, forming a homogeneous joint once the energy stops and the area cools. This process eliminates the need for threads or chemical bonding agents, ensuring clean and uniform seam strength.

Ultrasonic quilting works effectively on thermoplastic-based materials that can soften and fuse under ultrasonic energy. Nonwoven fabrics, polyester blends, nylon, and laminated composites are commonly used. The technology is widely applied in producing bedspreads, pillow covers, mattress covers, and thermal insulation layers. In addition, it is used in automotive interiors, medical textiles, and filtration materials where seamless bonding and particle-free surfaces are essential.

Fabrics with high thermoplastic content bond more efficiently because they melt uniformly under ultrasonic vibration. Multi-layer or thick materials may require higher power or slower processing speeds to achieve uniform bonding.

The amplitude of ultrasonic vibration determines how much energy reaches the fabric interface. Proper pressure ensures intimate contact between the fabric layers, preventing weak welds or surface damage.

The engraved pattern on the roller defines not only the visual appearance but also the distribution of welding points. Optimized designs improve both decorative quality and structural integrity.

An ultrasonic quilting machine bonds fabrics by harnessing high-frequency vibration energy to achieve molecular-level fusion. This process replaces traditional sewing with a faster, cleaner, and more precise bonding method. Its ability to create strong, seamless joints without threads or adhesives makes it a preferred solution across textile manufacturing sectors that demand efficiency, durability, and aesthetic consistency.

Copyright © ChangZhou AoHeng Machinery Co., Ltd. All Rights Reserved

English

English 中文简体

中文简体 русский

русский Español

Español