Modern cutting fabric machine installations use digital control systems to turn raw material into finished parts with minimal offcut. Programmable motion control, nesting algorithms, sensor feedback, and seamless CAD/CAM integration all combine to reduce wasted area, lower scrap rates, and shorten rework cycles.

Content

- 1 Precision motion control and its impact on yield

- 2 Advanced nesting algorithms and material utilization

- 3 Pattern recognition and markerless cutting

- 4 Real-time monitoring and closed-loop waste reduction

- 5 Automation of setup, repeatability, and workforce impact

- 6 Comparative metrics: expected waste reduction

- 7 Implementation checklist to minimize scrap

- 8 Final notes on return on investment

Precision motion control and its impact on yield

Closed-loop servo control for accurate paths

Closed-loop servo drives maintain position and speed with high repeatability. When step errors and mechanical backlash are minimized, parts nest more tightly and kerf variation stays consistent. That predictable kerf directly increases usable area per roll or panel and reduces the safety margins operators traditionally add to compensate for mechanical drift.

Micro-adjustments for stack and tension variance

Real-time micro-adjustments compensate for stack compression, fabric stretch, and conveyor slip. The control system measures actual travel and adapts cut paths so successive layers align within narrow tolerances, enabling higher layer counts per pass without increasing scrap.

Advanced nesting algorithms and material utilization

True-shape nesting versus rectangular nesting

True-shape nesting packs irregular parts tightly based on their actual contours rather than bounding boxes. Digital nesting reduces wasted gaps between patterns, often improving material yield by 5–20% depending on part complexity and fabric width.

Adaptive nesting with fabric roll tracking

When control systems receive live inputs about roll width, remaining usable length, or pattern orientation constraints, nesting regenerates to match the exact usable area. This prevents cutting into damaged zones and avoids conservative setup that discards more material than necessary.

Pattern recognition and markerless cutting

Vision systems to locate printed markers and defects

Cameras detect print registration marks, fabric flaws, or grain direction. The control system automatically adjusts pattern placement to steer parts away from defects and align grain-sensitive pieces, avoiding scrap created by manual misalignment.

Markerless layouts using contour detection

For patterned or asymmetric materials, contour detection lets the cutting fabric machine orient parts without preprinted markers. This reduces the need for manual marker placement and lowers setup time, which indirectly reduces waste from misaligned early production runs.

Real-time monitoring and closed-loop waste reduction

Live scrap metrics and automated correction

Dashboards display scrap percentage, offcut shapes, and location of frequent errors. When thresholds are breached, the control system can trigger path recalculation, lower feed speed, or pause the job for inspection. That automated response prevents the continuation of a problematic run that would otherwise generate large waste.

Data-driven maintenance to avoid quality drift

Predictive maintenance schedules derived from machine telemetry (motor currents, vibration, blade torque, laser power) keep cutting accuracy within spec. Preventing slow degradation avoids gradual increases in scrap that often go unnoticed until a full batch is affected.

Automation of setup, repeatability, and workforce impact

Automated job setup (upload pattern, apply nest, set layer count, load template) removes manual measurement variance. Repeatable setups reduce the learning-curve waste in changeovers and enable less experienced operators to run complex jobs with the same material efficiency as seasoned technicians.

Comparative metrics: expected waste reduction

| Feature | Typical impact on waste |

| True-shape nesting | Reduce gaps; +5–20% material yield |

| Vision-guided alignment | Avoid defect cuts; 2–10% less scrap |

| Closed-loop motion control | Tighter kerf tolerance; 1–5% savings |

| Automated setup & data alerts | Lower changeover waste; 3–8% savings |

Implementation checklist to minimize scrap

- Confirm fabric characteristics in the CAD/CAM system (elasticity, printed repeat, coated areas) before nesting.

- Calibrate kerf and stack compression values for each material and store them as templates.

- Enable vision inspection for printed patterns and defect avoidance on every roll change.

- Monitor live scrap metrics and set automated alerts for rapid intervention.

Final notes on return on investment

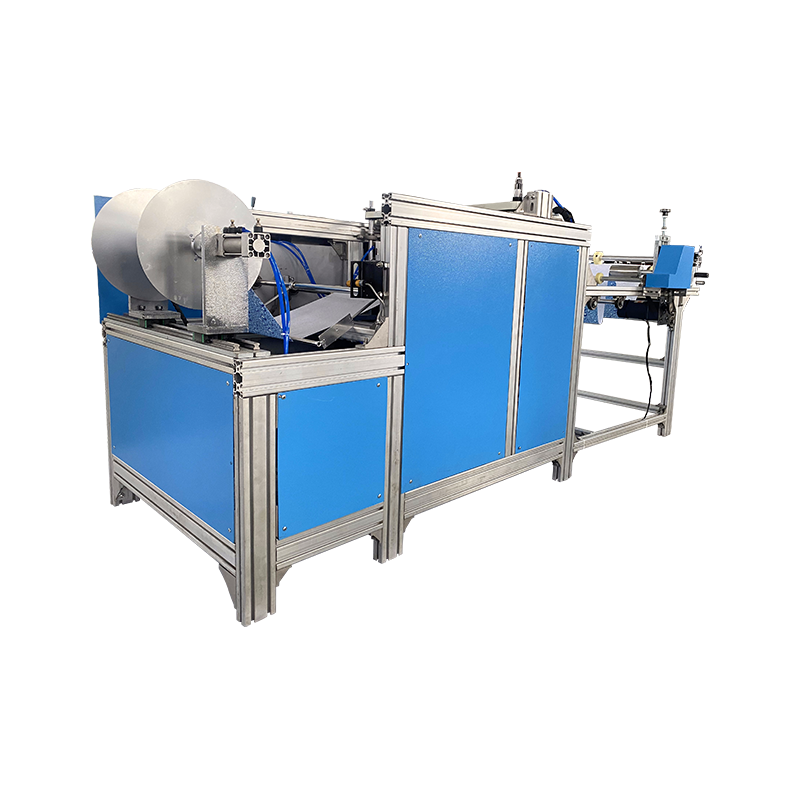

Reducing material waste increases effective throughput and reduces raw material purchases. For many shops, the combined effect of nesting, vision guidance, and closed-loop control produces a payback in months when material costs are high or part complexity demands precise placement. Integrating these digital control features converts the cutting fabric machine from a simple tool into a predictable, low-waste process step.

English

English 中文简体

中文简体 русский

русский Español

Español