Request A Quote

Content

Cutting fabric machines play a crucial role in modern textile production. They are designed to cut fabrics with precision, speed, and consistency, reducing labor costs and material waste. Whether for garment manufacturing, upholstery, or technical textiles, these machines improve operational efficiency.

Depending on production scale and fabric type, machines can range from small manual cutters to advanced computer-controlled systems capable of handling multiple fabric layers simultaneously.

Manual cutting machines are typically hand-operated and suited for sample making or low-volume production. They rely on human skill to guide the blade or rotary cutter accurately. Their main advantages are simplicity and low cost, but they require careful handling to avoid mistakes or uneven cuts.

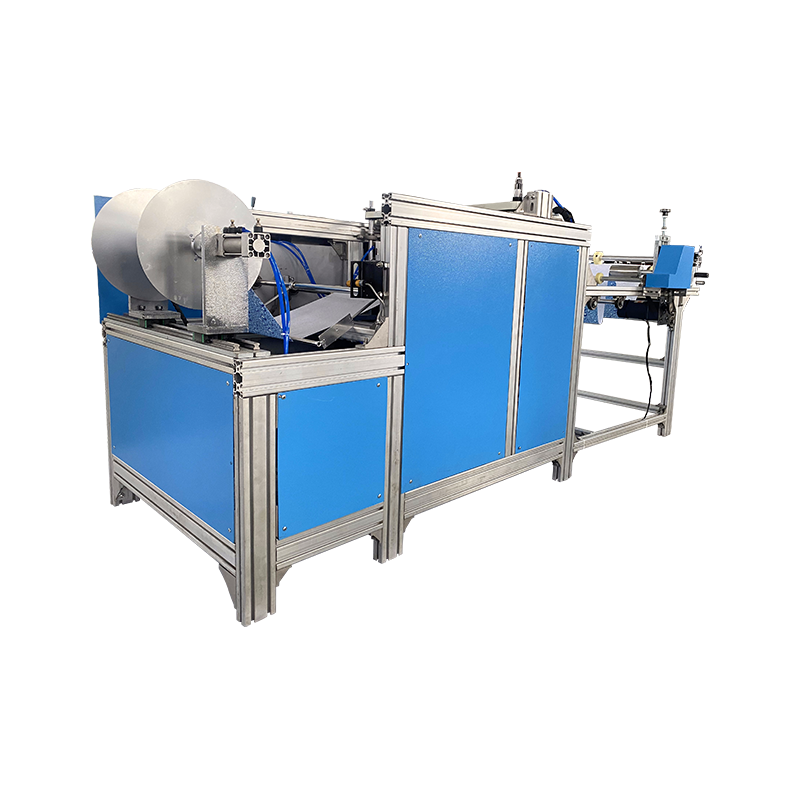

Automatic cutting machines, especially CNC models, are ideal for high-volume production. They use digital designs to cut patterns with minimal human intervention. These machines can process multiple fabric layers, reduce fabric waste, and provide repeatable precision for complex shapes. They are widely used in apparel factories and industrial textile operations.

Laser cutting machines offer high-precision cutting for delicate or intricate fabrics. The laser beam cuts without physical contact, preventing fraying and maintaining clean edges. They are suitable for synthetic fabrics, lace, and leather, and allow for rapid pattern changes without needing physical templates.

When choosing a cutting fabric machine, focus on features that impact efficiency, quality, and long-term usability:

Proper maintenance ensures longevity and optimal performance of cutting fabric machines. Follow these practices:

Costs for cutting fabric machines vary widely based on type, automation level, and capabilities. Key points to consider:

Budgeting for maintenance, spare parts, and operator training is essential to fully realize the benefits of your investment.

Different fabrics require different cutting approaches. Understanding fabric behavior ensures smooth operation and better results:

Here is a comparative summary of the main types of cutting fabric machines:

| Machine Type | Best For | Advantages | Cost Range |

| Manual | Small-scale production, samples | Low cost, simple operation, easy maintenance | Low |

| Automatic/CNC | Mass production, multi-layer cutting | High precision, reduces waste, repeatable patterns | Medium to High |

| Laser | Intricate designs, delicate fabrics, synthetic fabrics | Non-fraying cuts, fast, precise, minimal physical contact | High |

Copyright © ChangZhou AoHeng Machinery Co., Ltd. All Rights Reserved

English

English 中文简体

中文简体 русский

русский Español

Español